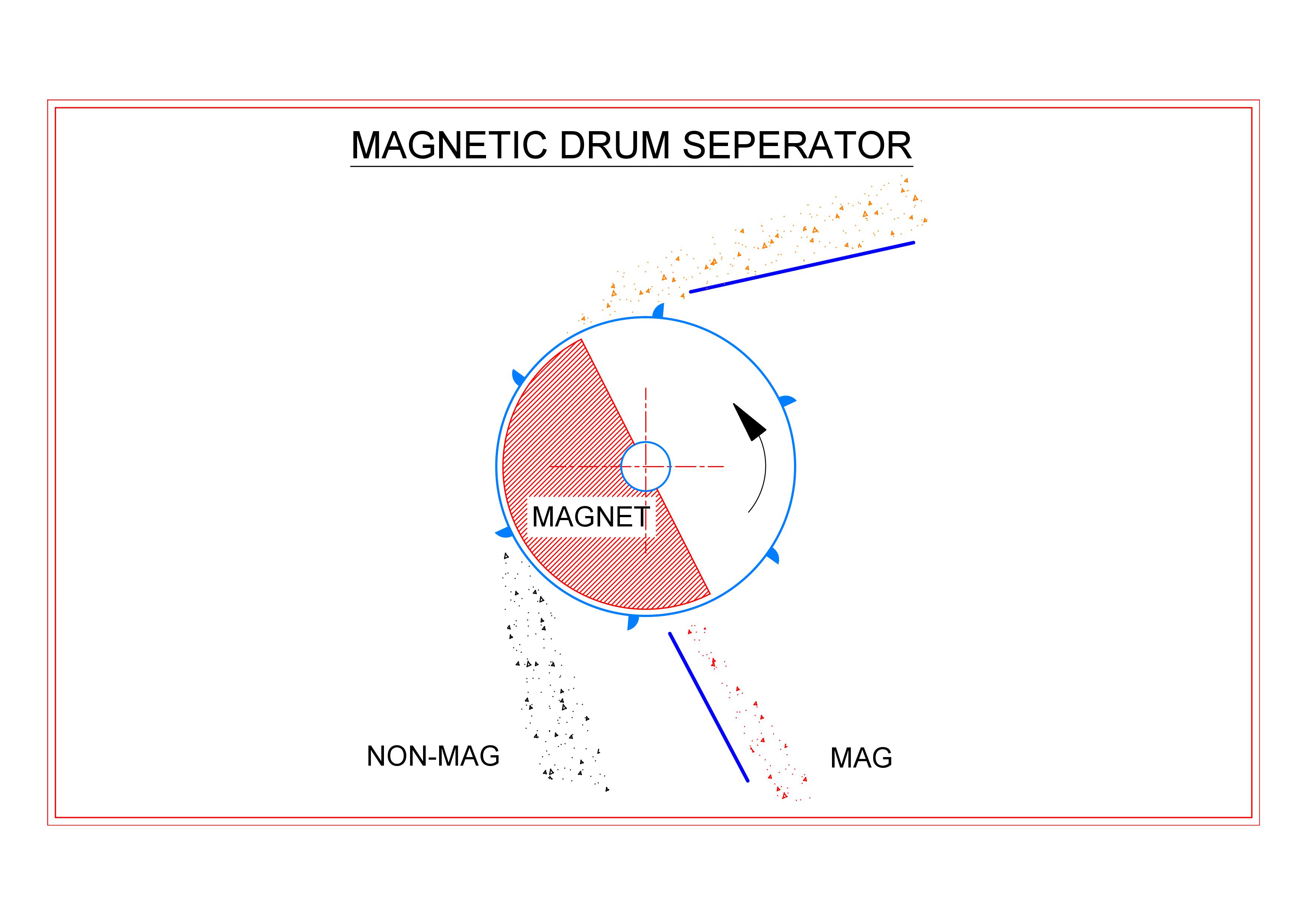

Drum Separator are designed for the continuous extraction of ferrous materials from a product being fed uniformly on to the face of the drum. As the material is fed onto the drum, ferrous materials are extracted and are firmly held to the drum face by the magnetic separator until they move away from the magnets influence and discharge, leaving any non-ferrous materials to free fall.

Permanent Drums have a 180 degree stationary magnet system within a revolving cover. The magnet system is constructed using fully stabilised strontium ferrite permanent magnets OR Neodymium Iron Boron magnets (Rare Earth Magnet). The magnets are mounted on to heavy-duty back plates, to optimise the magnetic strength directed at the product stream. This not only enhances the Drums performance but also reduces the magnetic fields in the shaft and bearings, helping to extend their service life.

For applications that require a much greater level of magnetic separation, Permanent Drum Magnets can be constructed using the highest grade of Neodymium Iron Boron magnets. High-Intensity Rare Earth Drums are capable of extracting fine ferromagnetic and paramagnetic materials, which may not be extracted using a standard Permanent Drum. Rare Earth Drums are most often fitted into totally enclosed housing.

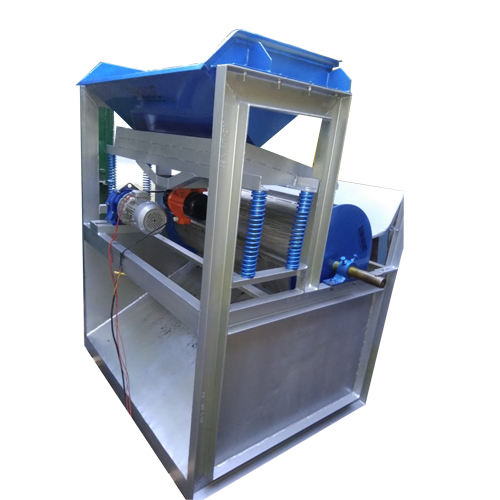

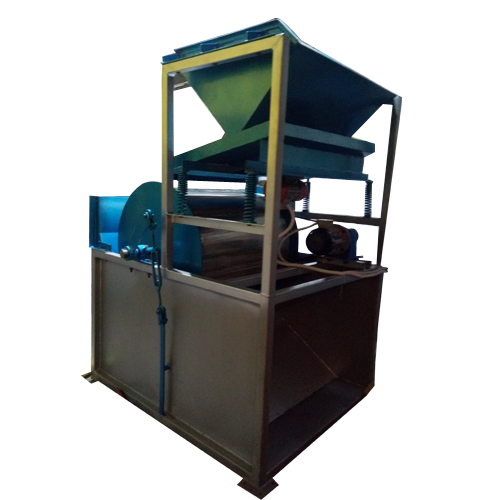

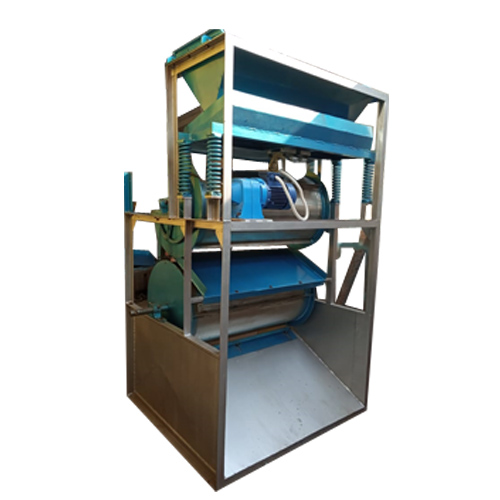

Image Gallery

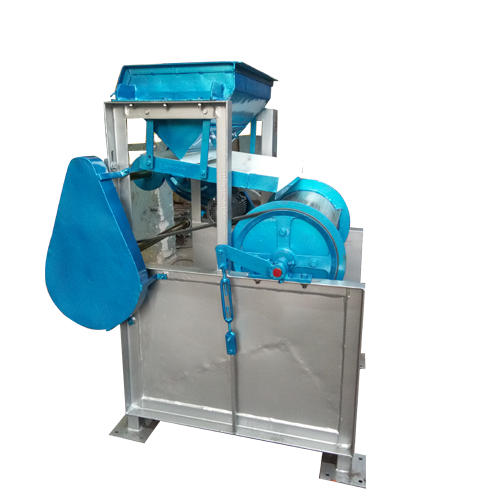

Permanent Magnetic Drum Separator

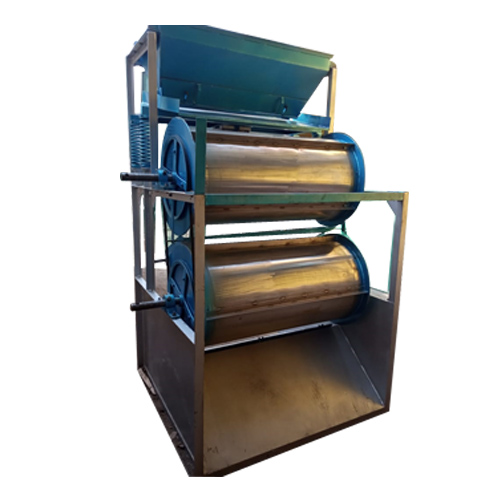

Permanent Magnetic Double Drum Separator

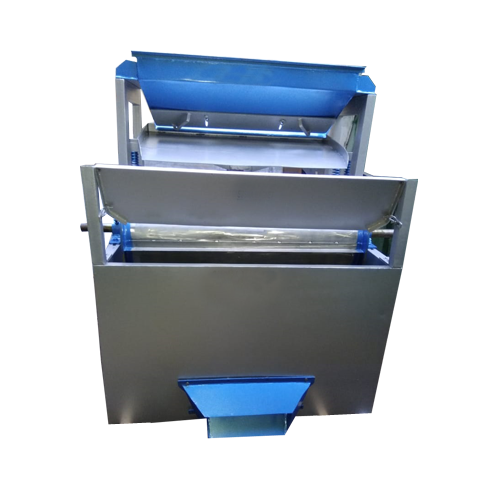

Permanent Magnetic Drum Separator

Permanent Magnetic Drum Separator

Permanent Magnetic Drum Separator

Permanent Magnetic Drum Separator

Permanent Magnetic Drum Separator

Permanent Magnetic Drum Separator

Permanent Magnetic Drum Separator

Double Drum Separator