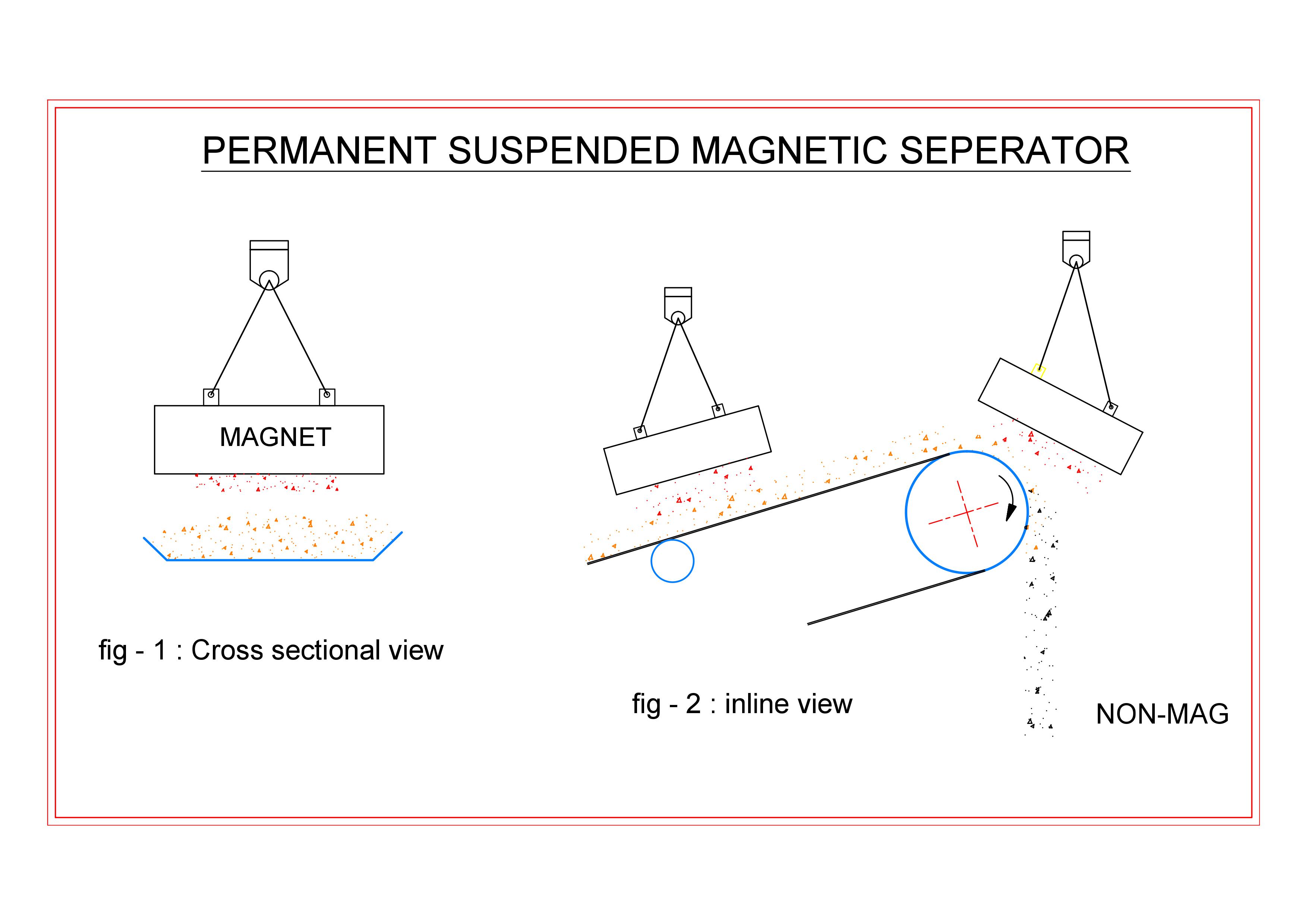

Suspended Permanent Magnetics are placed above open conveyors to arrest ferrous objects and fines found in grains, feedstuff, raw and processed products, dry chemicals, salt, ceramics, Clinkers in Cement Industry, Coal conveying in power plants and many other products. Suspended Permanent Magnets are used for separating big Ferrous particles like lugs, nuts, bolts, rivets, MS plates, angles, channels and tools from moving material on a conveyor belt. Suspended Permanent magnets are generally in big sizes depending upon the width and speed of the conveyor belt. They are provided with eye bolts, D shackle and sling /chains with turnbuckles for adjustments while mounting. Magnetic Separation Process: The Suspended Permanent Magnet is placed over the conveying belts carrying the material. This Suspended Magnet system arrests Ferromagnetic materials from a distance of 200 mm (8 inches) from feed material which is transported through the conveyor belt for the production process. This is one of the best separation equipment for conveyor belt applications. Placed in a welded framework, the magnet harbours a powerful permanent magnet capable of removing tramp iron from huge volumes. The most important thing is that it is a simple and cheap apparatus for protection of plants for crushing and grinding.

|

Standard Suspended Permanent Magnet |

|||||||

|

Model No. |

Length (mm) |

Width (mm) |

Height (mm) |

Max. Temp (?C) |

Magnet Type |

Gauss Strength |

Max Operating Height (mm) |

|

MAK0055 |

500 |

500 |

250 |

200 |

Ferrite |

1500±200 |

200 |

|

MAK0066 |

650 |

600 |

250 |

200 |

Ferrite |

1500±200 |

200 |

|

MAK0086 |

800 |

600 |

250 |

200 |

Ferrite |

1500±200 |

200 |

|

MAK0088 |

800 |

800 |

250 |

200 |

Ferrite |

1500±200 |

200 |

|

MAK0108 |

1000 |

800 |

250 |

200 |

Ferrite |

1500±200 |

200 |

|

MAK1010 |

1000 |

1000 |

250 |

200 |

Ferrite |

1500±200 |

200 |

|

MAK1210 |

1200 |

1000 |

250 |

200 |

Ferrite |

1500±200 |

200 |

|

MAK1212 |

1200 |

1200 |

250 |

200 |

Ferrite |

1500±200 |

200 |

Image Gallery

Suspended Permanent Magnet

Suspended Permanent Magnet

Suspended Permanent Magnet

Permanent Suspended Magnet

Permanent Suspended Magnet